How to the best resin category for application?

树脂化学品广泛用于电子和电气行业的灌封和封装,但并非一开始就能作出正确选择。由于有这么多树脂可供选择,决定哪种树脂最适合您的应用本身就是一项挑战。本文重点介绍不同类型的树脂特性和应用。

Resin chemicals are widely used in potting and packaging in the electronic and electrical industries, but the right choice can not be made at the beginning. Since there are so many resins to choose from, it is a challenge to decide which resin is most suitable for your application. This paper focuses on the characteristics and applications of different types of resins.

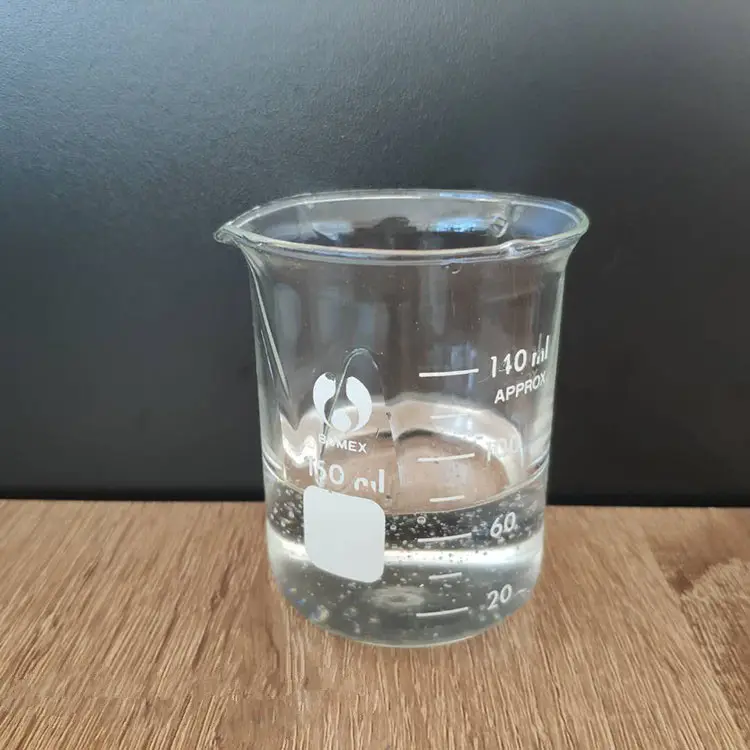

环氧树脂 Epoxy resin

环氧树脂因其优异的电气和机械性能以及对化学品和高温的耐受能力,在电子行业中广受欢迎。使用环氧树脂能够使部件防尘、防潮以及防止短路,并且由于标准环氧树脂比空气的导热性更好,因此可以更有效地使部件散热,延长使用寿命。

Epoxy resin is popular in the electronic industry because of its excellent electrical and mechanical properties and resistance to chemicals and high temperatures. The use of epoxy resin can prevent dust, moisture and short circuit. Because the standard epoxy resin has better thermal conductivity than air, it can more effectively dissipate heat and prolong the service life.

聚氨酯树脂Polyurethane resin

虽然环氧树脂在固化时是硬密封剂,但聚氨酯树脂通常是弹性体,在固化状态下更像橡胶,如果要封装的电路包含精密部件,这一点尤其有用。与环氧树脂一样,聚氨酯树脂具有耐化学性、防尘性和防潮性、优异的电气绝缘性并且与大多数金属和塑料等基板具有良好粘合性。与环氧树脂不同,聚氨酯在固化过程中的放热更低,即使是快速固化体系也是如此。聚氨酯树脂通常具有较低的连续工作温度范围,在其使用寿命的大部分时间内不得超过130°C。

Although epoxy resin is a hard sealant when curing, polyurethane resin is usually an elastomer, which is more like rubber when curing. This is especially useful if the circuit to be encapsulated contains precision components. Like epoxy resin, polyurethane resin has chemical resistance, dust and moisture resistance, excellent electrical insulation and good adhesion with most metal and plastic substrates. Unlike epoxy resin, polyurethane has lower heat release during curing, even for rapid curing systems. Polyurethane resin usually has a low continuous working temperature range, which shall not exceed 130 ° C during most of its service life.

有机硅树脂 Organic silicone resin

尽管不像环氧树脂和聚氨酯树脂那样应用广泛,但有机硅树脂用作封装树脂时确实具有一些明显的优势,因为固化产品在较宽的温度范围内具有高度的柔韧性、优异的耐化学性、防尘性和防潮性,以及良好的电气绝缘性能。有机硅树脂往往比环氧树脂或聚氨酯更昂贵,但非常适合需要较高连续工作温度(180°C以上)的场合。此外,使用硅酮体系时的放热温度确实非常低,确保了与热敏元件的兼容性。

Although it is not as widely used as epoxy resin and polyurethane resin, organic silicon resin does have some obvious advantages when used as packaging resin, because cured products have high flexibility, excellent chemical resistance, dust and moisture resistance, and good electrical insulation performance in certain temperature range. Organic silicon resin is often more expensive than epoxy resin or polyurethane, but it is very suitable for occasions requiring higher continuous working temperature (above 180 ° C). In addition, the exothermic temperature of the silicone system is really very low, which ensures the compatibility with the thermal sensor.

- Up to 1,200V, 720kW Capability in China-made EV Charging Stations247

- 20 Best-selling Products for the Christmas and New Year Holiday Season362

- Hu Kun, Vice President of LLDD, Visited the Embassy of Kazakhstan in Singapore7014

- Liu Zhai, Senior Vice President of IBI, was Invited to Participate in the 2024 Modern Logistics and Supply Chain Industry-Finance Cooperation Ecological Conference and Hami City Modern Logistics High-Quality Development Conference7051

- LLDD of IBI Went to Ningxia Logistics Group for Inspection and Exchange9813